APPLICATION NOTE: CONTINUOUS LAMINATION

PROCESS OVERVIEW:

In the Continuous Lamination process chopped reinforcements or other continuous core fabrics are fed onto a light weight Pearlveil carrier.

The entire laminate is usually then completed with a second layer of Pearlveil on top. Pearveil then carries the entire composite layup through a curing oven before being cut to length. The laminator may contain shaping rollers for corrugated panels. In other applications the panels may be flat, such as laminated signs.

SI VEIL DESIGN CONSIDERATIONS:

Pearlveil is uniquely designed for the Continuous Lamination process.

Veil Thickness:

Typical Pearlveil materials used in Continuous Lamination are between 3 mil and 10 mil.

Width:

Pearlveil may be customer specified at any width up to 120 inches (3.048 m) wide.

Fiber Orientation:

Pearlveil lightweight veils are made of nonwoven, continuous strand glass fibers. The unique design provides excellent wet out and assists in the elimination of air entrapment in finished panels.

Color:

All SI Veils are clear in color, making the glass transparent in the finished part.

Binder Options:

- Series 100 Binder is more soluble and usually selected for Continuous Laminating.

- Series 600 Binder may be selected if the process requires higher tensile properties.

- Other: Consult Factory.

Electrical Properties:

Pearlveil offers excellent electrical resistance for finished parts.

Corrosive Properties:

All SI Veils highly corrosive resistant for parts intended for use in harsh, acidic conditions.

Finish Appearance:

Pearlveil provides outstanding laminate finishes eliminating optical distortion of printed fabrics.

Smoke and Fire Suppression:

All SI veils consist of glass mineral fibers that are non-toxic and do not burn.

Post Lamination Finishing:

- The translucent color allows for enhanced resin pigmentation or post painting

- Parts can be sanded before post painting

- The glass fibers shear cleanly when holes are punched into the parts

PACKAGING:

Each roll is attached and wound on a heavy duty 4-inch I.D. cardboard core, immediately sealed against contamination in a polyethylene bag and identified with a unique product specific label. Pearlveil, based upon quantities, is usually shipped on a 45 inch x 45 inch wooden pallet. Optional packaging is available.

STORAGE:

For best performance, all veils should be stored upright in locations with temperatures between 50°F (10°C) and 85°F (30°C) with a relative humidity below 80%.

QUALITY:

All Pearlveil products are produced in the United States and meet the demanding quality requirements within the industry.

WARRANTY:

See Schmelzer Industries Product Warranty.

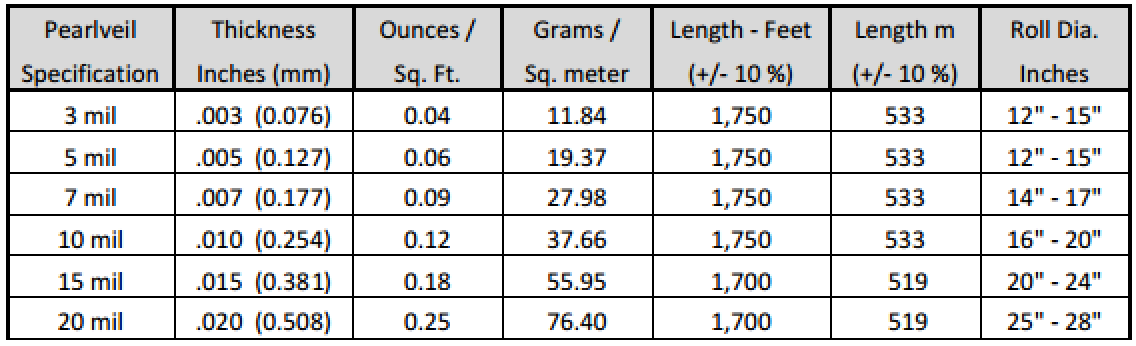

TYPICAL SI VEIL SPECIFICATIONS FOR CONTINUOUS LAMINATION PROCESSES: