Filament Winding

PROCESS OVERVIEW:

Filament Winding is an open molding process of wrapping continuous reinforcements around a rotating mandrel to produce closed-form hollow parts.

The process is capable of economically producing simple cylindrical, hollow parts of high hoop strength such as lengths of pipe, duct work, cylinders, storage tanks, hollow poles and pressure vessels.

In the most common Filament Winding process, the reinforcement materials are first passed through a resin bath before application to the mandrel. An autoclave curing process is usually

preferred for dry winding.

Light weight Pearlveil is commonly used when the vessel interior, exterior or both surfaces require a smooth finish. Usually, this will improve fluid laminar flow properties.

SI VEIL DESIGN CONSIDERATIONS:

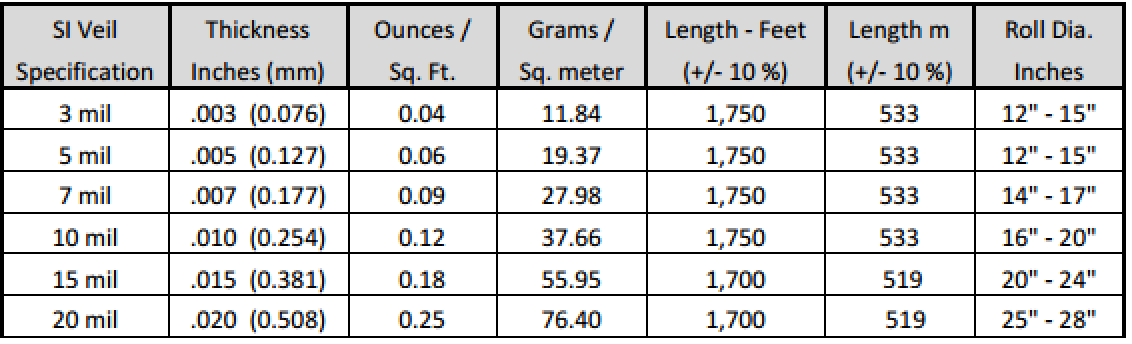

Veil Thickness / Weights:

The designer should select a veil that is capable of carrying resin to the mandrel while also having the tensile strength to not tear out during application.

Typically, a Pearlveil will be selected that ranges from between 3 mil and 10 mil thick.

Width:

Schmelzer Industries provides slit width rolls to the customer’s specification. Often they are between 3 inches and 10 inches.

Color:

All SI veils are clear in color, making the glass transparent in the finished part. This is a benefit when the filament winder winds safety or information documents just below the surface.

Filament Orientation:

Pearlveil is specifically designed for high processing strength in Filament Winding applications. The lightweight veils are nonwoven, continuous strand glass fibers for outstanding wet-out.

Binder Options:

- Series 100 Binder is more soluble and usually selected for filament winding

- Series 200 Binder may be selected if the process requires higher tensile properties

Electrical Properties:

Pearlveil offers excellent electrical resistance for finished parts.

Corrosive Properties:

Pearlveil is highly corrosive resistant for parts intended to be used in harsh, acidic conditions.

Smoke and Fire Suppression:

All SI Veils consist of glass mineral fibers that are non-toxic and do not burn.

PACKAGING:

Each roll is attached and wound on a heavy duty 4-inch I.D. cardboard core, immediately sealed against contamination in a polyethylene bag and identified with a unique product specific label.

Pearlveil, based upon quantities, is usually shipped on a 45 inch x 45 inch wooden pallet. Optional packaging is available.

STORAGE:

For best performance, all veils should be stored upright in locations with temperatures between 50F (10C) and 90F (35C) with a relative humidity below 80%.

QUALITY:

All Pearlveil products are produced in the United States and meet the demanding quality requirements within the industry.

WARRANTY: See Schmelzer Industries Product Warranty.

About Schmelzer Industries LLC.: Schmelzer Industries Inc, headquartered in Somerset, Ohio is a glass fiber manufacturer, developer and supplier of quality veils and reinforcements into the composites industry.

TYPICAL PEARLVEIL SPECIFICATIONS FOR FILAMENT WINDING:

Consult factory for additional options.